Practical Examples of Value Creation: How will digital transformation create real value for a manufacturing company? Let’s use the factory floor as a testbed ...

As your organization takes steps to become a Great Digital Business, a critical concern for the Leadership Team will be creating value – simply put, what’s in it for me? (or, more accurately, what’s in it for the company?) This is a nuanced question – are we talking about the value created for the shareholder as we focus on building a Great Stock, or the value created for our employees and our customers as we focus on building a Great Company?

This is also a critical question when pitching process change and investments in people, process, and technology. Vendors will happily list off exciting features and amazing capabilities of their offerings. But where are the hard-dollar, metrics-driven justifications that the check signers need to see?

More to the point – how will these capabilities, and game-changing benefits, create value for my company? Competition for resources is fierce – time, people, and cash investments. There must be a compelling reason for the change, one that creates value that really matters to the organization.

Let’s use the factory floor as a testbed for our examples. How will digital content management, workflow automation, and real-time connectivity create real value for a digital manufacturing company? We will break this up into three separate conversations, focused on our three different stakeholders, and create simple metrics to show real value – easy formulas that can be modified to fit your operation’s size and culture.

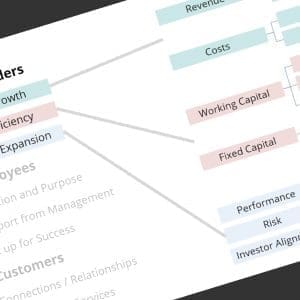

Value for the Shareholders

Also known as Total Shareholder Return, this is the raw, capitalist form of value creation. There is a ton of information available on what creates long-term shareholder value; in its simplest form, the value of a stock is driven by three basic levers:

Earnings Growth – The day-to-day operations of a company; the objective here is to increase cash earnings. Historically, automation of internal Operations has focused on driving down costs; automation also enables a company to scale their operations, efficiently handling an increase in sales volume without a corresponding growth in the cost required to support those sales.

Example Metric – Cost of Poor Quality

Translating an idea like the Cost of Poor Quality into a few simple measures for improvement will help people see cost savings that flow directly to the bottom line. How will these metrics change after a digital shop-floor communication and information platform is in place – one that delivers real-time notifications of issues, content management for work instructions and orders, and automated data collection?

- Scrap Rate

- Current scrap rate of $100K per month; process changes will lower that by 50%

- $50K / month cost reduction

- Customer Returns

- Returns tracking at $250K per month; process changes will lower that by 75%

- $62.5K / month cost reduction

- Rework

- Rework generates $200K overtime per month; process changes eliminate >90%

- $180K / month cost reduction

These numbers are representative for a $50-100M company; plug in your own estimates for Current Rates and Expected Improvements to estimate the impact on your business.

Capital Efficiency – What does your business do with all the cash generated by operations? When your cash is tied up in inventory or invested in manufacturing capacity, digital capabilities will enable drive Return On Invested Capital; there will always be a need for efficient Operations, plus tight collaboration to pull in new people and new capabilities to your Team.

Example Metrics – Working Capital

Poor quality impacts the balance sheet as well – warranty returns must be budgeted for. In addition, manufacturing automation can join with Lean Manufacturing practices to reduce and optimize the WIP and Finished Goods inventories required to maintain high customer service.

- Warranty Reserve

- Current reserve is $2M; quality improvements will reduce warranty claims by 10%

- $200K cash flow improvement

- Inventory Reduction

- Current WIP averages $2.5M; flow improvements will lower that by 15%

- $375K cash flow improvement

Multiple Expansion – A fancy term for that interesting gap between a company’s imputed value, based on actual performance, versus the current price on the open market. Market price can be heavily impacted by the perception of risk and volatility – and your organization’s relative performance versus their peers in the market. Admittedly, it is tough to justify changes in Wall Street’s sentiments on a shop floor system; there may be some Risk Management claims to be made, but nothing that is easily measurable. Let’s skip this type of value creation – there are more measurable areas available!

Value for the Employees

The counterpoint to a great Stock is a great Company – one, for example, where employees have the right skills, the right motivations, and are highly engaged. Employee Engagement is a bit of a buzzword, and when first introduced to an organization, it can be a difficult concept to grasp. A basic description of Employee Engagement can take the form of three simple questions:

- Do I understand and believe in the company’s purpose – do I know where we are going?

- Do I get the support I need from my manager?

- Do I have the tools and processes needed to be successful at my job?

That last one is the hook for justifying digital improvements on the shop floor. Your Manufacturing team is a critical component – along with Customer Service, they are truly the ones closest to your customers. For these key members of the team, it can be frustrating and disheartening when the tools are inadequate and the processes in place seem to get in the way. A highly engaging environment makes the right investments and actively iterates on internal and external processes.

Example Metrics – Engagement

An effective manufacturing automation platform streamlines data entry, reducing errors and freeing up the folks on the floor from low-value-add paperwork. In addition, work instructions are captured and presented at the right place and the right time – for higher quality work and a fast-paced training environment.

These improvements can lower costs, but here we are specifically looking at changes that will improve the overall Engagement score.

- Employee Engagement

- Shop floor Engagement scores average 52; process improvements will increase by 3 points for the impacted areas

- 2 points overall Engagement increase

Once again, these numbers are representative; plug in your own estimates for the impact such investments will have on your Team.

Value for the Customer

There are two parts to our Great Company focus; engaged employees are important, but we exist to create and sell products and services to our customers. Your Great Digital Business has two out of five important components that are focused on creating value here …

Connections with Customers – Really listening and understanding their needs, developing products and services that fulfill those needs, and fulfilling them with a fanatical focus on customer service.

Example Metrics – Customer Service

The questions that arise here are important – but not as important as where you get your answers. Digital capabilities make it easier than ever to listen to your customers and focus on their needs – but you must turn your attention externally!

- On-Time Delivery

- 6 month rolling average is 90%; better material availability will increase by 5%

- Sustained 95% OTD for key customers

- Customer Satisfaction

- OTD and Quality improvements address historical pain points for customers

- 10% overall CSAT increase

Information in our Products – The introduction of information as a new and differentiating feature in your products and services can truly change your role in the market and your value to the customers. When thinking about Smart, Connected Products, it’s critical to focus on the entire Value Chain; how can your Manufacturing teams derive benefits from this information?

This is a valid type of value creation for any organization, but it feels like a stretch to attribute benefits to the shop floor. Digital Manufacturing will absolutely get smarter when connected to products in the field, but we will skip this piece of the conversation for now.

Plenty of Ammunition

Remember, we are focused on clear and simple metrics that tie directly to our company’s ideas around value creation – value that truly matters to our various Stakeholders. Each new initiative does not have to have an answer for everything. But when we do claim value, we must show metrics that are measurable, material, and meaningful to the company.

This is typically when a strong Leadership Team adds to the conversation – with open communication, clarity of purpose, and a focus on maintaining the balance between Great Company and Great Stock. With the right Digital investments, your organization can truly create value.

Just make sure you are ready to measure it!

31 January, 2021

- Creating Enterprise Value with your Digital Transformation

- Creating Digital Value for Stock Holders

- Creating Digital Value for Employees

- Creating Digital Value for Customers

- Digital Transformation on the Manufacturing Floor

Comments (0)