Each functional area in your company needs to understand the skills and strengths that they bring to a Digital Transformation effort; why do they deserve a “seat at the table”? It's time for the folks in Operations to step up - with their depth of experience with Eliminating Waste and Eliminating Complexity, Operations can and should play a critical role. (part of a series)

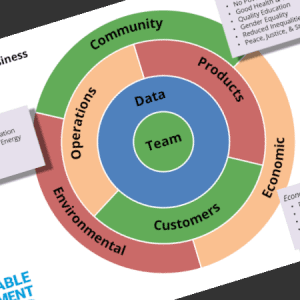

The everyday internal operations of your company should be the most mature area for applied Digital Technology. Experience is a great teacher, and internal processes in the enterprise has been subject to evolutionary change for many years. This should give the Operations team a significant advantage in understanding the potential for a Great Digital Business – and the kind of non-digital work required to make the technology-enabled stuff scalable and sustainable.

What was that? Almost sounds like a contradiction in terms – but there is truth and wisdom in our collected experience. I like to point out that “when you automate a mess, you get an automated mess”- it’s an old truism from my digital youth, and still holds true today. Operations teams have developed skills and techniques in understanding how to streamline the business by taking cost and effort out of their daily work. Operations is in a key position to leverage this experience, and show Digital Leadership in a number of important ways.

- Eliminate Waste: The specific types of waste targeted by the principles of Lean Manufacturing are all applicable in your Digital conversations. Operations can leverage their skills in Lean to identify and eliminate waste (overproduction, wait time, transportation, extra processing, unnecessary inventory, excess motion, defects) in all aspects of the business – including how you connect with customers, how you handle and process data, even how teams can interact and collaborate.

- Eliminate Complexity: Similarly, your Operations team should be the most skilled at applying the Pareto principle – understanding that 80% of the value is realized by 20% of your effort. This 80/20 rule can be applied in many ways – and when Operations uses it to eliminate the complexity introduced by the 80% of the “stuff” you are managing (tasks, projects, time) that is generating only 20% of the results – the results can be amazing.

It should be clear that eliminating waste and reducing complexity will free up a lot of important resources – not the least of which are Time and Attention. Your Digital Transformation efforts will be much more impactful with focus; the Operations team will truly be providing the most impact when they help your organization focus on the critical few things required to get done. But we won’t stop there – Operations has other areas where they can provide leadership:

- Team Communication: Another standout tactic of Lean Manufacturing practitioners is the idea of a Daily Stand-Up meeting; as the day begins, cross-functional teams get together to review the hot items of the day, follow up on yesterday’s priorities, and make sure the collective focus is on the critical customers and shipments for today. No technology has to be involved; the focus is on simple charts and open conversation among the team. This practice is a great example that other functional areas can learn from – direct collaboration at the point of impact.

- Management by Metrics: Effective Operations teams have learned to use metrics – specifics, data, facts – to understand what is happening around them and focus their attention where it needs to be focused. Again, this is an area where many have experienced success with minimal technology – it’s not about how you process the data, it’s how you use the information to change your behavior. Don’t get me wrong – technology often comes into play as the metrics get more sophisticated, and opportunities for improvement become more pointed. But the technology is secondary to the impact that we are trying to create.

- Be the Beta User: The R&D engineers are talking about information as a new and differentiating feature for the products we sell to our customers. But the idea of using sensors and smart devices to measure and monitor machines is not new – Operations has been experimenting with Machine-to-Machine (M2M) technology for years. So why not get these two groups together – and try out some of these information-enabled machine ideas internally? Your organization can act like a primary beta-user for these new products – and R&D can do some experimenting and valuable learning (aka failing) with the most understanding type of customer.

The best part of this last point – your learning events (aka mistakes) impact internal operations, and not external customer systems. It’s also a great way for key folks on the product management team (especially the engineers!) to get their own hands-on experience, to demystify this magical technology, and make it digestible for the conservative organization.

13 January, 2019

- How Finance can Participate in your Digital Transformation

- How Sales & Marketing can Participate in your Digital Transformation

- How Operations can Participate in your Digital Transformation

- How IT can Participate in your Digital Transformation

- Finance Participation in your Great Digital Business – The Slides

- IT Participation in your Great Digital Business – The Slides

Comments (0)