Who should take the leadership and ownership role for defining your "ecosystem of data"? This simple story illustrates the challenge for complex value chains.

In the industrial manufacturing world, I’m seeing an interesting pattern develop. It comes up in strategic and tactical conversations with small, medium, and large sized firms, along various points in the value chain to the ultimate end customer. And the overriding pattern is organizations waiting to take the first step.

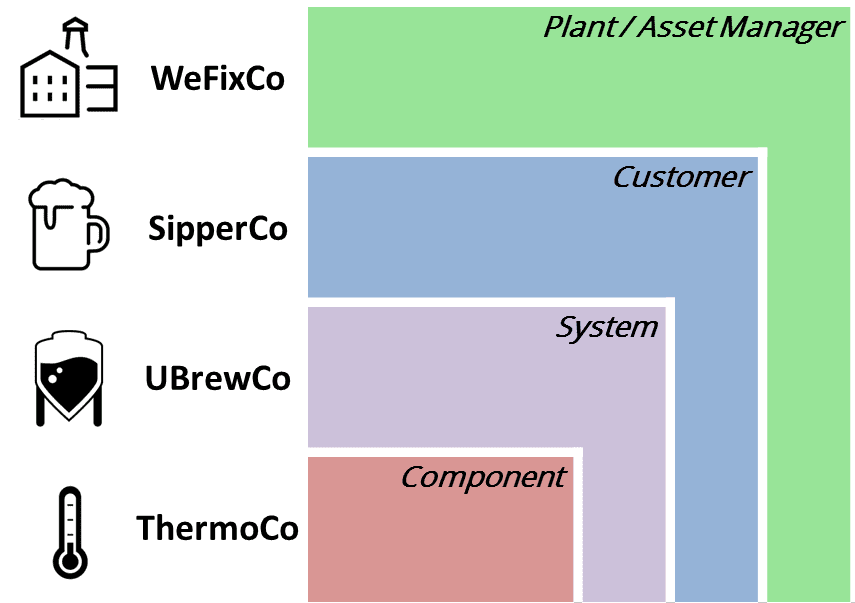

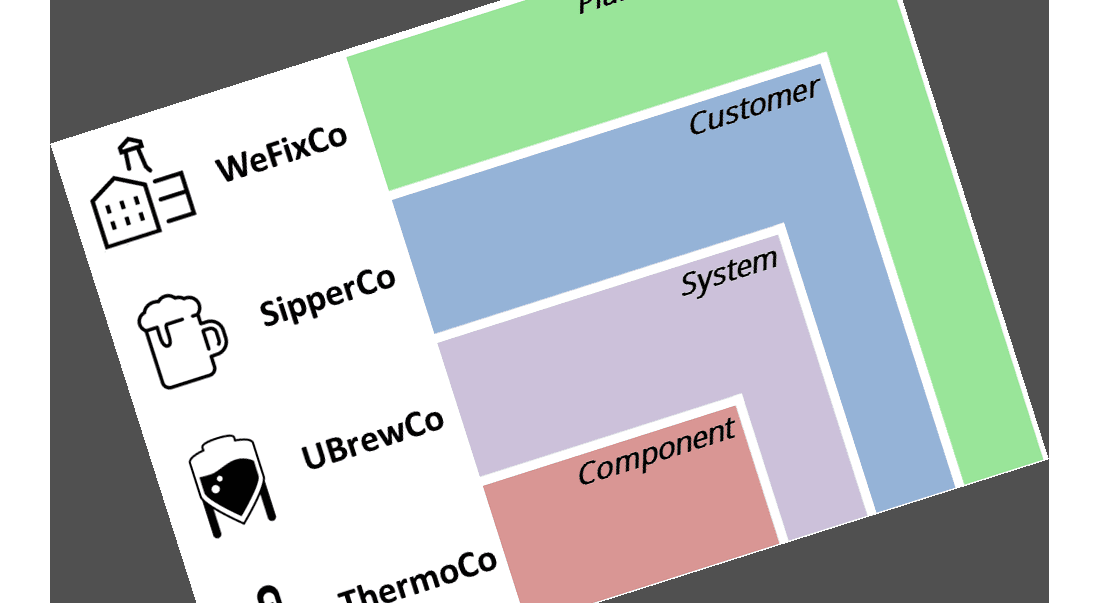

Consider this typical Manufacturing Hierarchy; sophisticated components are put together to build complex systems, which populate large plants and drive huge processes. Or smaller, bespoke processes of high value – like a microbrewery, cooking up a wonderful selection of regional stouts, ales, and wits.

In our tasty little example((The story, all names, characters, and incidents portrayed in this post are fictitious. No identification with actual persons, places, buildings, and products is intended or should be inferred. No animals were harmed in the making of this motion picture.)), the components manufacturer (ThermoCo) is building highly sophisticated thermostats. These are purchased as self-contained units by our system builder (UBrewCo), who puts together pumps, valves, meters, thermostats, actuators, and displays – along with some nicely formed sheet metal and other materials – to create a brewhouse (the “hot side” of a beer-making production line).

The end customer in all of this (SipperCo) is going to purchase a number of UBrewCo’s brewhouse systems, and set them up in a plant. And since SipperCo is branching out to a number of cities, they may want a series of manufacturing facilities set up – and will possibly contract with service provider (WeFixCo) for plant and asset management.

![]() Now, when the urge to implement the Internet of Things strikes this industry, who might take the lead? ThermoCo has some electronics already on their devices, which are by all accounts a (the?) critical element in the overall system. But it’s tough for ThermoCo to grow share without introducing a significant new feature, so they want to differentiate by adding sensors, providing monitoring “in the cloud”, and delivering real-time predictive maintenance analytics to guarantee maximum uptime. Clearly, one might say, it makes sense for ThermoCo to build the solution – the “ThermoCloud”.

Now, when the urge to implement the Internet of Things strikes this industry, who might take the lead? ThermoCo has some electronics already on their devices, which are by all accounts a (the?) critical element in the overall system. But it’s tough for ThermoCo to grow share without introducing a significant new feature, so they want to differentiate by adding sensors, providing monitoring “in the cloud”, and delivering real-time predictive maintenance analytics to guarantee maximum uptime. Clearly, one might say, it makes sense for ThermoCo to build the solution – the “ThermoCloud”.

However (says conservative ThermoCo), it’s probably the system builder’s play. UBrewCo brewhouses incorporate a PLC controller that already hooks up to plant level monitoring systems. Thermocouple feels they just need to add sensors – but they need to wait until UBrewCo provides interface specs. And since UBrewCo controls the PLCs (reasons ThermoCo), they’ll probably be developing the monitoring and predictive stuff. It seems reasonable, then, the solution should be a “UBrewCloud”.

However (says conservative ThermoCo), it’s probably the system builder’s play. UBrewCo brewhouses incorporate a PLC controller that already hooks up to plant level monitoring systems. Thermocouple feels they just need to add sensors – but they need to wait until UBrewCo provides interface specs. And since UBrewCo controls the PLCs (reasons ThermoCo), they’ll probably be developing the monitoring and predictive stuff. It seems reasonable, then, the solution should be a “UBrewCloud”.

Of course, UBrewCo also takes the opportunity to dodge the bullet; they are just one of many systems installed in SipperCo’s plants. Clearly (says pragmatic UBrewCo), it makes sense for a more holistic, plant-wide monitoring solution. Why, just think how much more accurate the predictive maintenance will be, when it takes so many inputs from so many components and systems? Obviously, the ultimate solution will be the “SipperCloud”.

Of course, UBrewCo also takes the opportunity to dodge the bullet; they are just one of many systems installed in SipperCo’s plants. Clearly (says pragmatic UBrewCo), it makes sense for a more holistic, plant-wide monitoring solution. Why, just think how much more accurate the predictive maintenance will be, when it takes so many inputs from so many components and systems? Obviously, the ultimate solution will be the “SipperCloud”.

Hold on (says focused SipperCo) – we are in the business of making tasty beers for thirsty people. We would expect our asset management subcontractors to have a system like that – it just makes sense, as they are doing the same basic service – monitoring systems and providing maintenance across many different manufacturing platforms. In the end, revenue from services is the big driver here – so it makes sense that we are talking about the “WeFixCloud”.

Hold on (says focused SipperCo) – we are in the business of making tasty beers for thirsty people. We would expect our asset management subcontractors to have a system like that – it just makes sense, as they are doing the same basic service – monitoring systems and providing maintenance across many different manufacturing platforms. In the end, revenue from services is the big driver here – so it makes sense that we are talking about the “WeFixCloud”.

Our services company will have a say as well – WeFixCo points out that they are just the end user of all of this equipment. This is all predicated on adding COGS to these components and systems (sensors and communications), and WeFixCo has little control over product companies and their engineering plans. We are happy to help with the requirements (says busy WeFixCo), as we deeply understand the impact – but we are clearly not the ones to build this thing.

You may have noticed, by the way, that I skipped over the dealers and distributors that work with ThermoCo and UBrewCo – that is a whole side conversation, another dimension to complicate things. To be sure, they are a critical component of the value chain – delivering service and training, and typically the critical conduit for replacement parts. Why not address the challenge with “DealerCloud”?

The challenge here is real; I’ve sketched this picture out a number of times, and each time it is met with nods of agreement – this is apparently an intractable challenge, an immovable obstacle, a traffic jam at a crossroads. Everyone seems to be waiting for the next person to make the move. And everyone has a solid reason why it makes sense for someone, anyone, other than themselves, to make that initial investment.

Can you see ways to break through? What is your take on this challenge – and how does this apply in your industry?

Join in the conversation in the comments below; I will let it run for a few days before publishing Part 2, talking about some of the next steps businesses are taking to get the ball rolling.

* Icon credits – all from The Noun Project (Thermometer by Aaron K. Kim, distillery by Evgeniy Artsebasov, Conical Fermenter by Mark Caron, Beer by NAMI A)

29 May, 2016

Comments (0)